Product overview

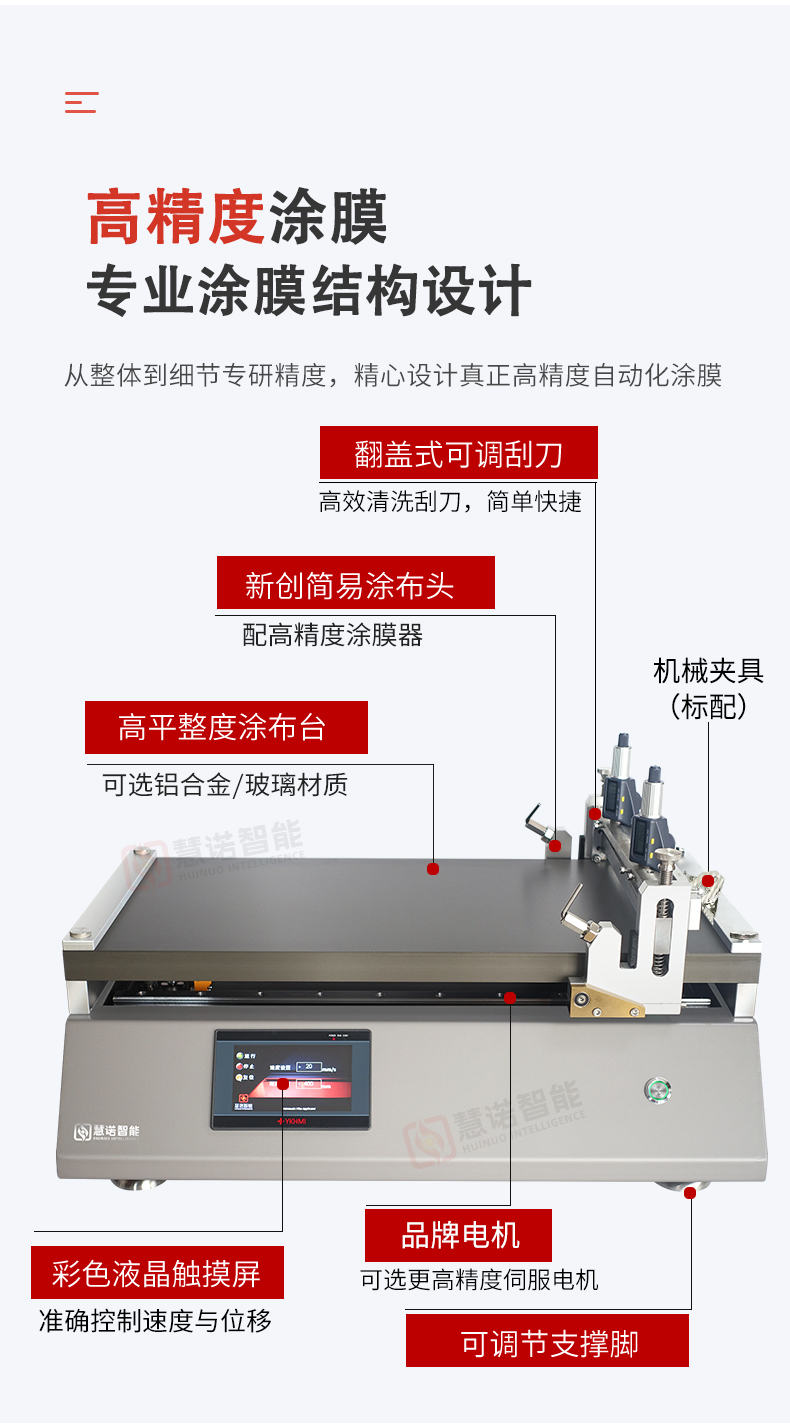

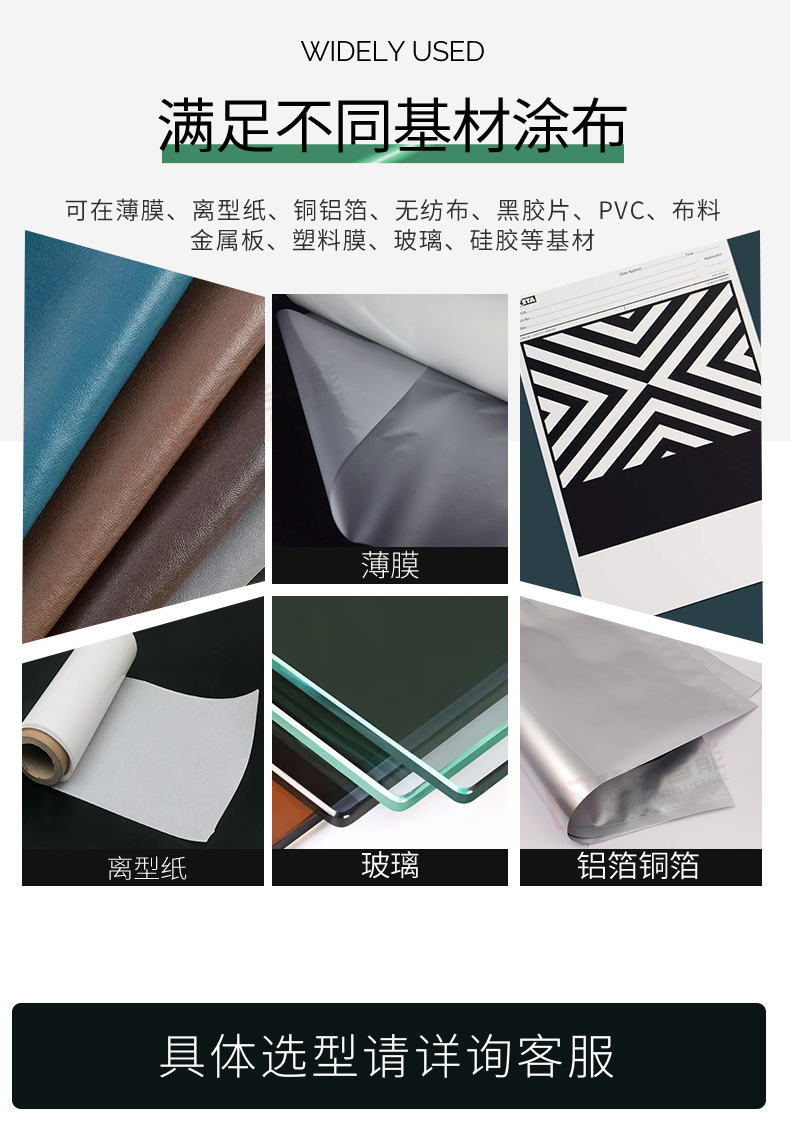

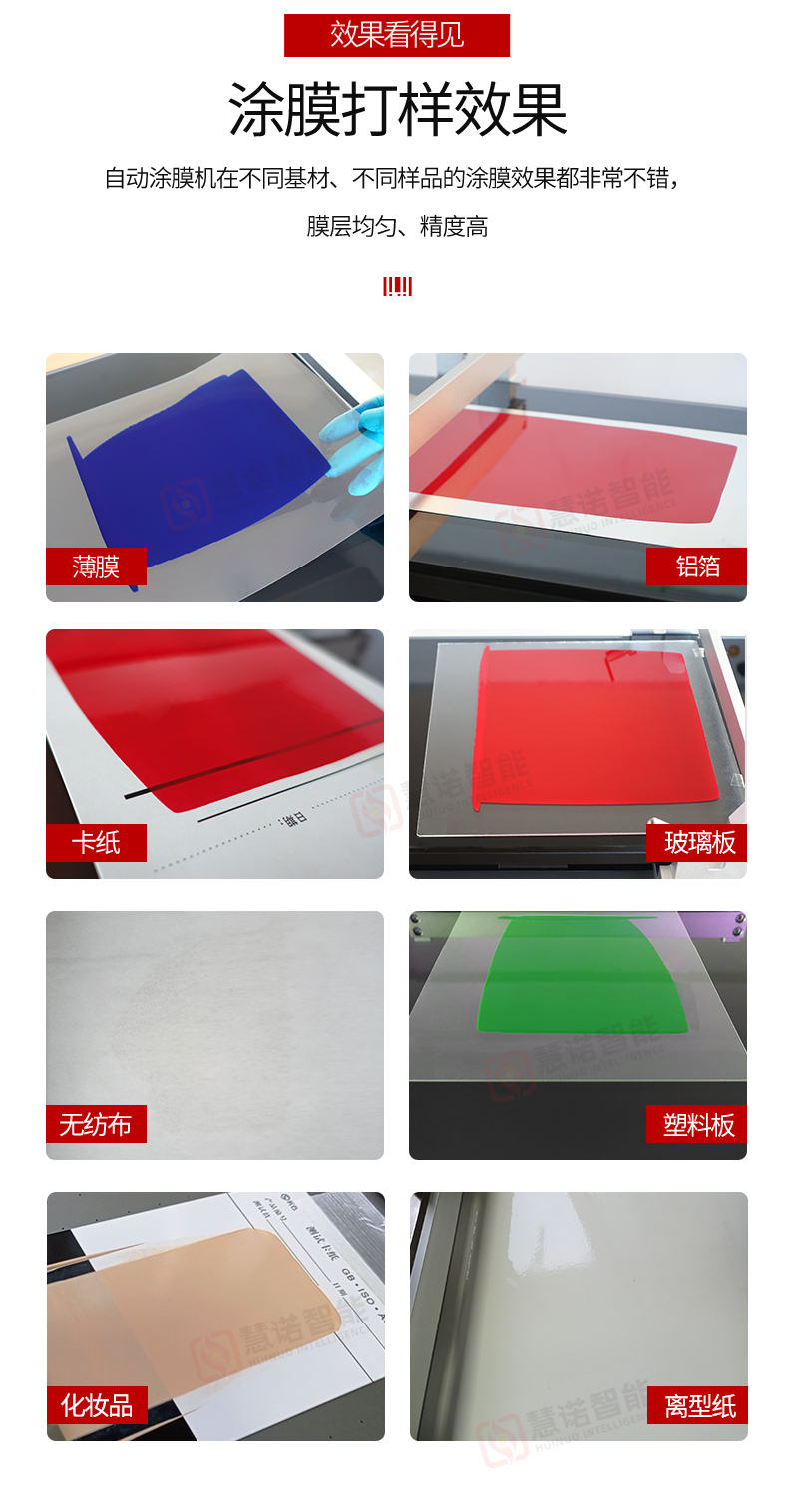

Automatic coating machine is used for coating film in the laboratory equipment, instead of manual coating, automatic coating film, improve the accuracy and efficiency of coating film. The working principle of the experimental automatic coating machine is to uniformly coat the sample on the substrate to form the required film by controlling the coating head and coating parameters.

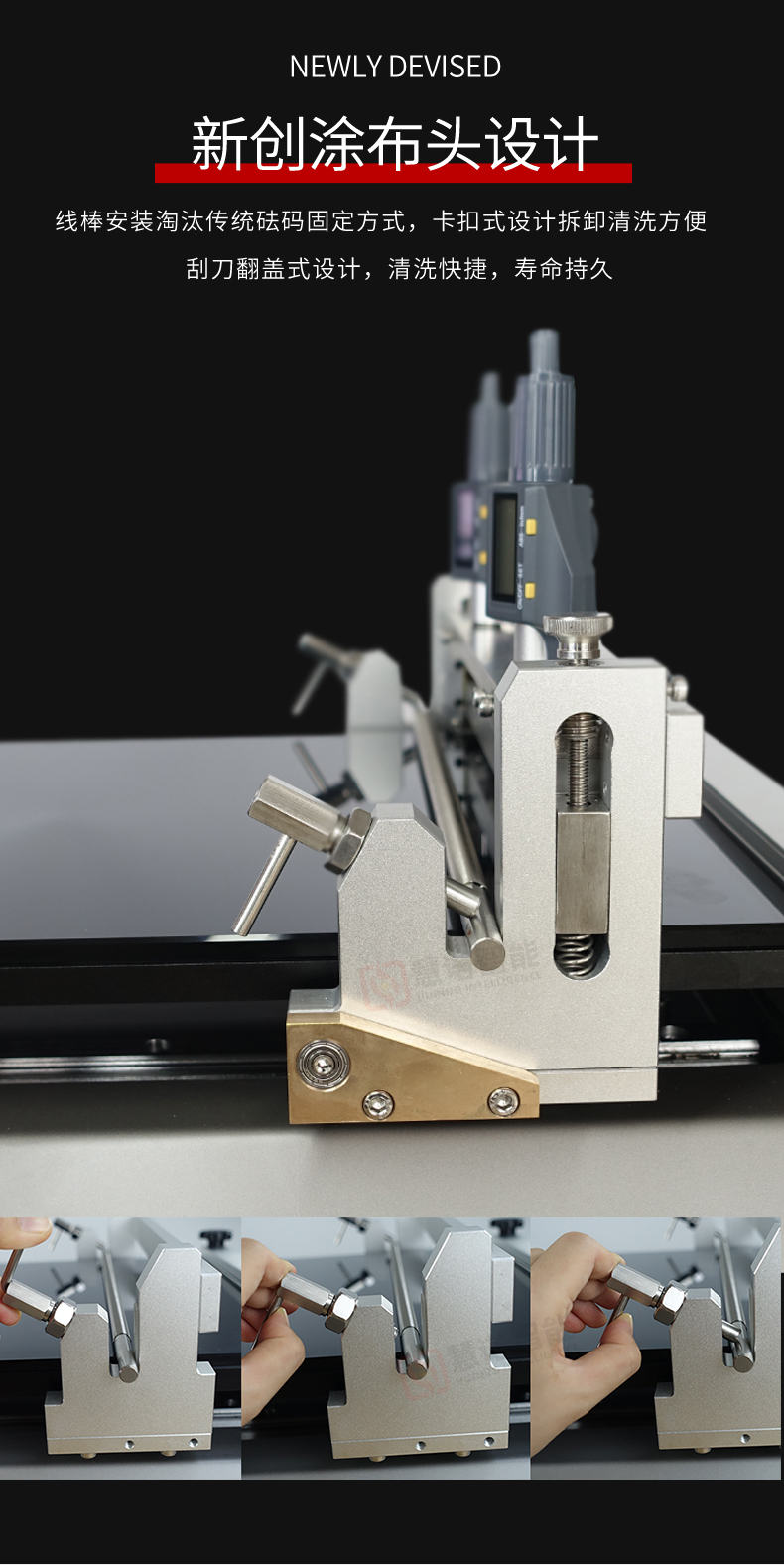

This film coating machine is a wire bar scraper coating machine, with two functions of wire bar coating and scraper coating, the new wire rod installation method and flap scraper head greatly improve the coating efficiency, easy to clean, with speed control and coating length adjustment functions, suitable for high-precision automatic coating in the laboratory, in the university research institute, new materials, lithium, glue, resin and other laboratories for film proofing.

Technical parameter

Model number |

TM3000 |

Coating method |

Wire rod coating + scraper coating |

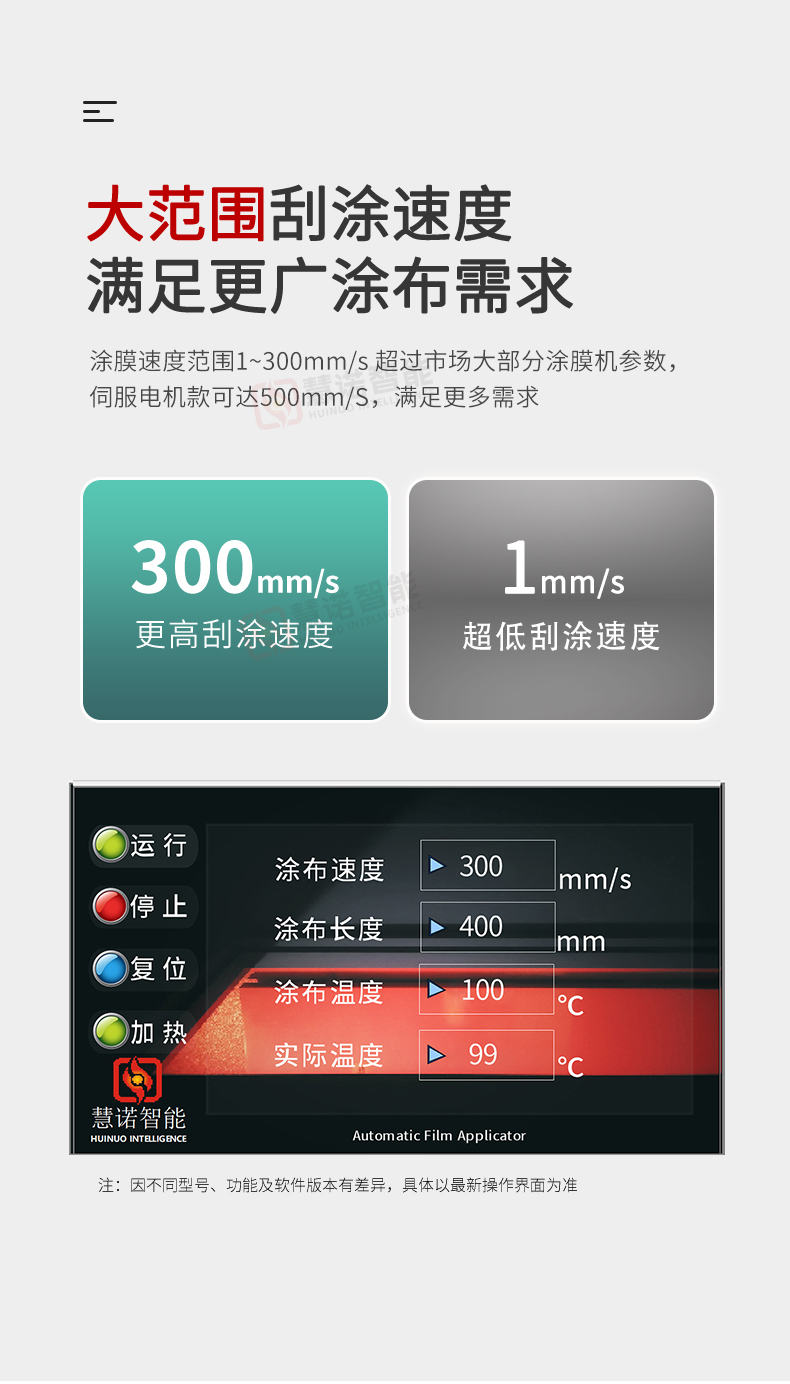

Coating rate |

1~300mm/s stepless speed regulation (customizable) |

Substrate fixation method |

jig |

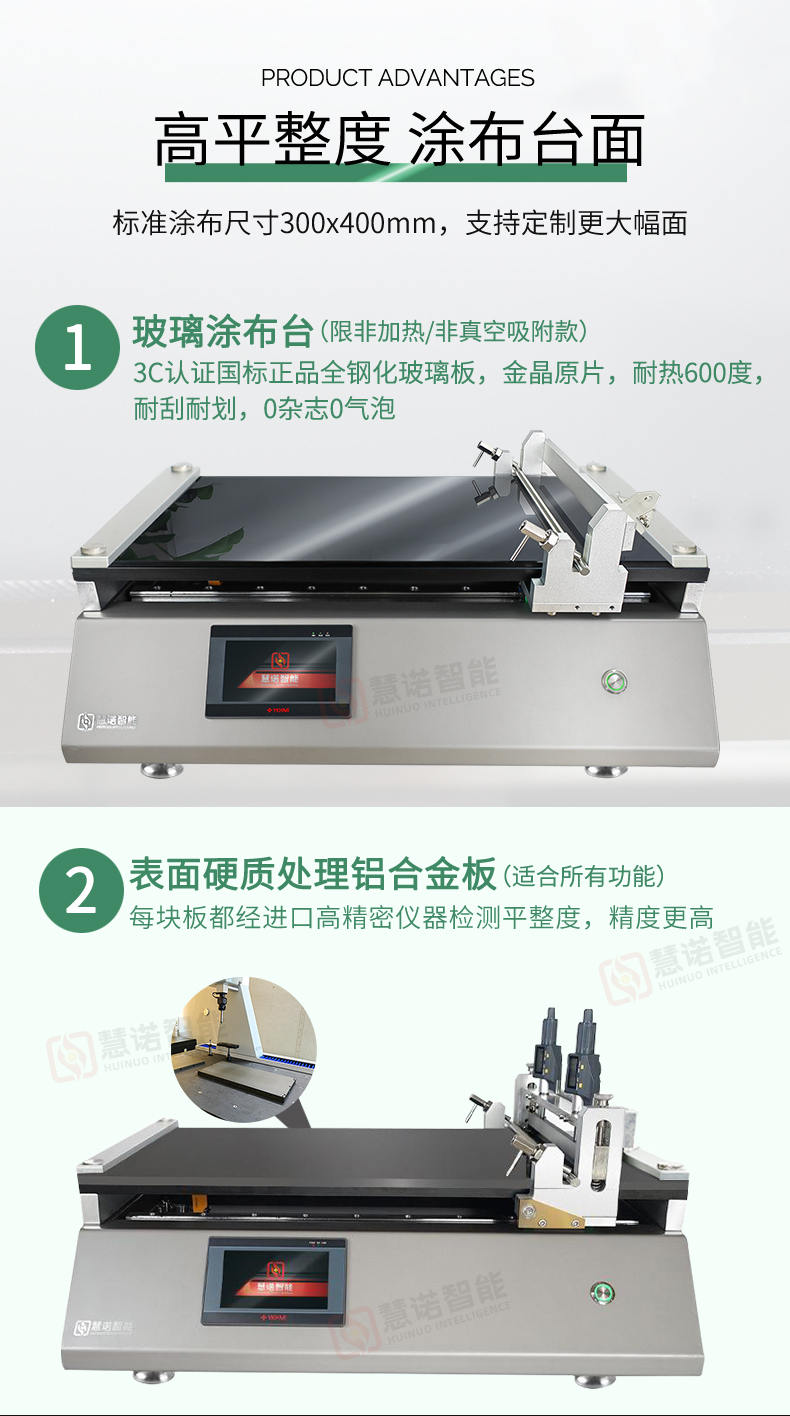

Coating table material |

Glass plate |

Coating platform size |

300*600mm |

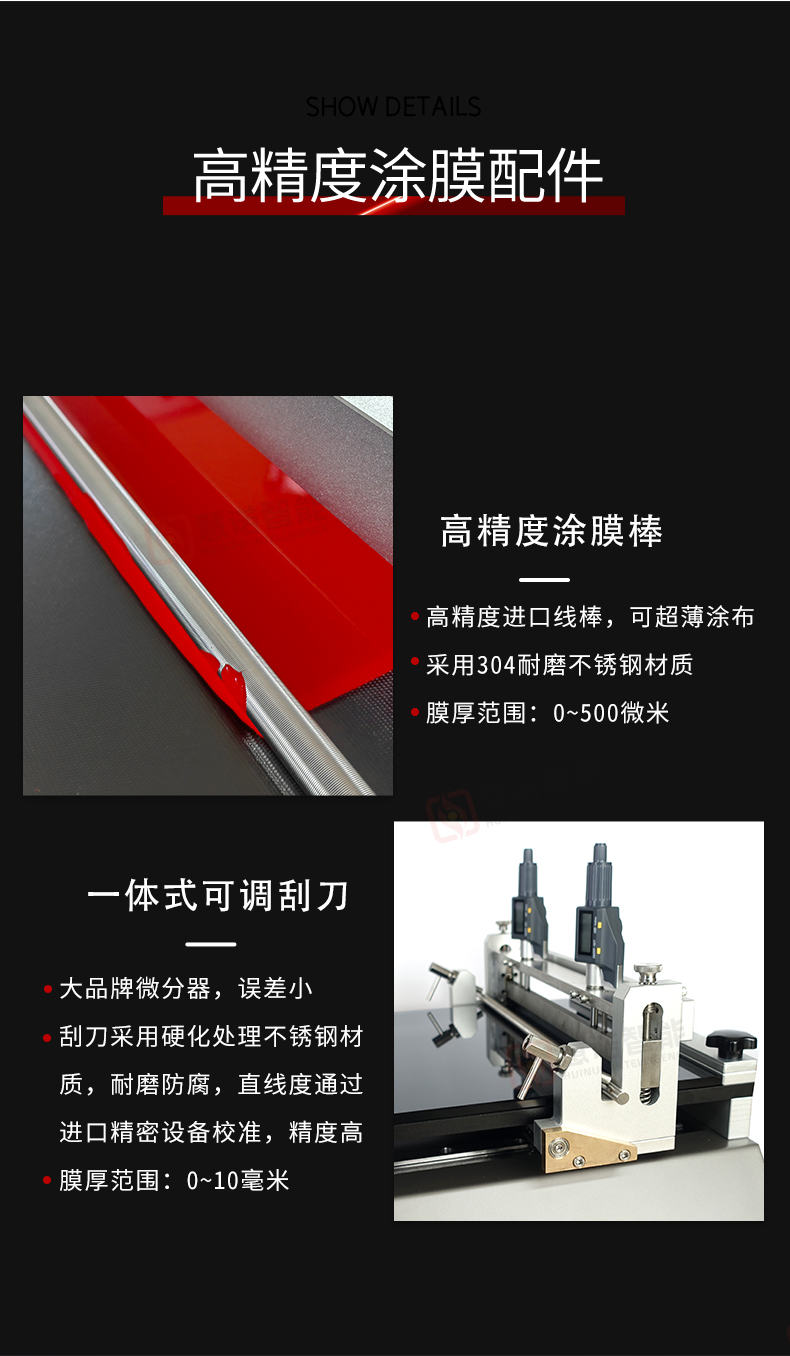

Wire rod coating thickness range |

Different rod size thickness is different, with high precision imported wire rod |

Wire rod coating accuracy |

+ / - 0.001 mm |

Coating format |

300mm*400mm (customizable) |

Display screen |

Color LCD touch screen |

Host power supply |

220V/50HZ (110V/60HZ can be customized) |

Overall dimension |

658*438*205mm (L*W*H) |

Optional function |

Heat, vacuum adsorption |

Blade coating thickness range |

0.1~10mm (flap design is easy to clean) |

Scraper material |

Die steel |

Blade coating width |

300mm |

Blade coating accuracy |

+ / - 0.003 mm |

power |

400w |

Operation language |

Chinese (English can be customized) |

Huinuo TM3000 wire rod scraper automatic coating machine Small coater-Flim Applicator-NBCLAB - Lab Testing Instruments

Huinuo TM3000 wire rod scraper automatic coating machine Small coater-Flim Applicator-NBCLAB - Lab Testing Instruments